test5

-

B2B erotic apparel export opportunities for wholesalers seeking compliant sourcing, scalable MOQs, and reliable shipping partners.

B2B erotic apparel export opportunities remain a pragmatic growth avenue for responsible manufacturers. Export demand expands where social norms and purchasing power evolve in parallel. Retailers and distributors seek suppliers who can deliver compliant files, consistent dye lots, and predictable lead times. Suppliers who document technical specs and testing cut clearance delays and reduce buyer friction. Successful exporters focus on private-label clarity, SKU rationalization, and modular collections that scale. Building trust through sample reliability, clear MOQ tiers, and transparent freight terms unlocks repeat business. Data from trade shows and verified B2B platforms helps prioritize target regions. With measured investment in compliance and logistics, small and mid-size makers can capture profitable export orders with limited upfront risk.

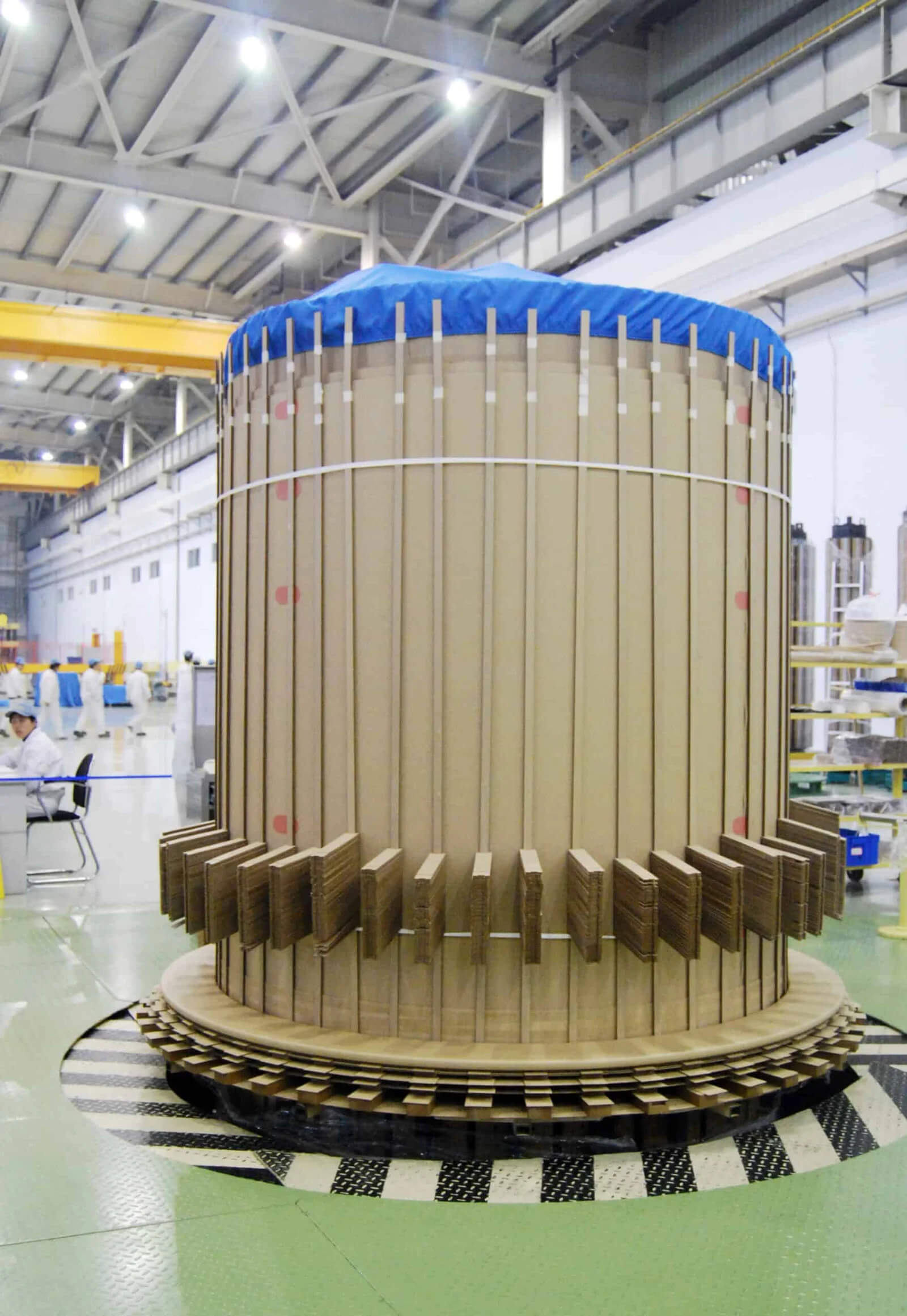

What Are Silicon Steel Laminations?

Transformers are the backbone of power systems, but their performance is directly tied to the quality of the magnetic core. A major pain point for manufacturers and users is core loss, which increases operational costs and reduces efficiency. If the wrong material or design is used, transformers suffer from high eddy current losses, heating, and audible noise. The solution lies in using silicon steel laminations, which minimize losses while maintaining mechanical and electrical stability. This choice directly impacts efficiency, cost, and long-term reliability.

Silicon steel laminations are thin sheets of iron alloyed with silicon (typically 2–4%) used in transformer cores to reduce hysteresis and eddy current losses. By stacking insulated laminations rather than using a solid core, the design interrupts current loops, lowers core losses, improves efficiency, and enhances magnetic performance. Grain-oriented silicon steel (GO) further optimizes performance by aligning magnetic properties with the direction of flux flow.

Transformer cores are usually made of solid steel blocks for durability.False

Solid cores would produce excessive eddy currents and losses. Laminated silicon steel is used to minimize these effects.

Adding silicon to steel increases its electrical resistivity and reduces hysteresis losses.True

The 2–4% silicon content improves resistivity, making steel ideal for transformer laminations.

1. Why Silicon Steel Is Used

| Property | Benefit in Transformers |

|---|---|

| High Electrical Resistivity | Reduces eddy current losses |

| Low Coercivity | Reduces hysteresis losses |

| High Permeability | Efficient magnetic flux conduction |

| Grain Orientation | Enhances flux alignment, lowers losses |

| Mechanical Strength | Enables precise lamination stacking |

2. Laminations vs Solid Core

| Feature | Solid Steel Core | Silicon Steel Laminations |

|---|---|---|

| Eddy Currents | Very high | Greatly reduced |

| Efficiency | Poor | High |

| Heat Generation | Excessive | Controlled |

| Noise Levels | Higher | Lower |

| Cost Efficiency | Low lifecycle value | High lifecycle value |

3. Types of Silicon Steel Used

- Non-Grain-Oriented (NGO): Magnetic properties are uniform in all directions; typically used in motors and small transformers.

- Grain-Oriented (GO): Magnetic domains aligned along rolling direction, optimized for transformer cores with high efficiency.

- High-Permeability Grain-Oriented (Hi-B): Advanced version with extremely low core loss, used in high-voltage and ultra-high efficiency designs.

4. Case Example: Efficiency Impact

A 1000 kVA distribution transformer with a grain-oriented silicon steel core consumes 30–40% less no-load loss compared to one made with non-grain-oriented laminations. Over its lifetime, this can save tens of thousands of dollars in energy costs.

5. Technical Insight

- Thickness of Laminations: Thinner laminations (0.23–0.30 mm) are preferred for high-frequency or high-efficiency applications because they reduce eddy currents.

- Insulation Coating: Each lamination is coated to prevent electrical conduction between sheets, further minimizing losses.

- Stacking and Geometry: Precision stacking reduces air gaps, ensuring consistent flux flow and lower noise.

How Do Laminations Reduce Eddy Current Losses?

One of the main challenges in transformer core design is eddy current loss. When alternating magnetic flux passes through a solid steel core, it induces circulating currents (eddy currents) within the metal. These currents generate unwanted heat, reduce efficiency, and can cause premature insulation breakdown. Left uncontrolled, eddy current losses significantly increase operating costs and shorten equipment life. The industry solution is the use of laminated cores. By replacing a single solid block with insulated thin sheets, eddy current paths are interrupted, drastically lowering core losses.

Laminations reduce eddy current losses by dividing the transformer core into thin insulated sheets of silicon steel, which restrict the path available for circulating currents. Since eddy current loss is proportional to the square of lamination thickness, using thinner laminations greatly minimizes heating, improves efficiency, and enhances transformer reliability.

Sustainability, safety, and certification trends

Sustainability increasingly affects B2B erotic apparel export opportunities as buyers demand certified production. Certifications such as OEKO-TEX and GRS reduce approval friction in eco-conscious markets. Recycled fibers and low-impact dyeing help buyers satisfy end-customer preferences while protecting brand reputation. Chemical-free finishes and nickel-free hardware cut allergy claims and return rates. Buyers often request supplier audit reports and social compliance documentation. Investing in sustainability can justify moderate price premiums and lead to longer contractual relationships. Clear sustainability claims backed by certificates strengthen bids in higher-margin retail channels.

JSY: Your Premier Erotic Lingerie Wholesale Partner

JSY (Jishiyuan Garment Co., Ltd.) has established itself as a leading force in wholesale intimate wear. With over 15 years of experience, JSY specializes in designing, manufacturing, and distributing intimate apparel. The company operates a modern 10,000 m² production facility with monthly capacity exceeding 200,000 garments. JSY’s commitment to quality is demonstrated through successful Sedex audits.

JSY’s comprehensive erotic lingerie wholesale services extend beyond simple product supply to include full business support for retail partners. The company offers design consultation, trend analysis, and customization services to help retailers differentiate their offerings. Advanced quality assurance programs ensure consistent product excellence, while flexible ordering options accommodate various business sizes and requirements.

JSY maintains strong relationships with fabric suppliers and component manufacturers, ensuring access to premium materials and innovative technologies. The company’s global distribution network enables efficient delivery to international markets, supported by experienced logistics teams. For retailers seeking reliable erotic lingerie wholesale partnerships, JSY provides the expertise, capacity, and commitment necessary for mutual success. We invite you to contact JSY today to explore how our comprehensive wholesale solutions can support your business growth and market expansion.

List of export readiness actions

-

Compile accredited test reports and fiber certificates.

-

Produce graded samples across five sizes for validation.

-

Define tiered MOQ and sample pricing clearly.

-

Lock freight forwarder and customs broker with apparel expertise.

-

Prepare bilingual product specs and packaging mockups.

Explaining the export readiness actions clarifies priorities for suppliers. Accredited tests reassure buyers and speed customs checks. Graded samples lower return risk by proving fit across sizes before bulk runs. Tiered MOQs allow buyers to trial SKUs without heavy capital commitment. A specialist freight partner avoids last-minute classification issues that delay delivery. Bilingual specs reduce onboarding friction and accelerate buyer decisions. Prioritizing these actions raises professionalism and markedly improves the odds of winning export contracts.

Export cost drivers and mitigation

| Cost Driver | Typical Impact | Mitigation |

| Freight & duties | High | Consolidate shipments, optimize Incoterms |

| Testing & compliance | Medium | Batch sampling and accredited labs |

| Returns & defects | Variable | Incoming QC and clear acceptance criteria |

Using the comparative table prioritizes mitigation actions for exporters. Consolidating shipments reduces per-unit freight and duty burden. Accredited lab sampling prevents customs surprises and saves detention costs. Incoming QC denies defective batches before shipment, lowering costly returns. Focusing on these levers first reduces overall landed cost quickly. Buyers prefer suppliers who proactively manage these risk areas. Exporters who implement these mitigations improve margins and maintain repeat orders across competitive markets.

Risk management, contracts, and insurance

Contract clarity and insurance protect margins when pursuing export deals. Define acceptance criteria and inspection windows in purchase agreements. Use staged deposits to align cash flow with production milestones. Purchase marine insurance to protect shipments against loss and damage. Maintain a contingency supplier list for critical components to avoid production stoppages. Specify IP protections for exclusive prints and limited designs in contracts. Clarify Incoterms, duty responsibility, and return policies up front to avoid disputes. Regular supplier audits and KPI tracking reduce operational surprises and preserve buyer trust.

Frequently Asked Questions

What documentation do buyers request most often for B2B erotic apparel export opportunities?

Buyers typically prioritize compliance and traceability documentation when evaluating suppliers for export orders. The most requested items include accredited chemical test reports, fiber and composition certificates, and third-party inspection records. These documents help buyers meet their own market regulations and speed customs clearance in target countries. In addition, buyers often request graded sample sets across multiple sizes, packaging mockups, and lead-time guarantees. For private-label deals, buyers may require proof of social compliance and facility audits. Suppliers that prepare a standardized compliance packet reduce the time to contract and inspire buyer confidence. Providing these documents upfront positions suppliers as export-ready and minimizes negotiation friction.

How should small suppliers price for international wholesale while remaining competitive?

Small suppliers should calculate full landed cost before quoting international wholesale prices to remain competitive. Start by determining factory cost per SKU, including trims and labor. Add testing and documentation costs prorated per order. Estimate freight and duty to derive a true landed cost. From there, set a wholesale margin that provides room for retailer markup and your desired profit. Offer tiered pricing for order sizes to encourage larger commits. Present transparent landed-cost breakdowns to buyers to reduce haggling and build trust. Pilot small regional markets to refine pricing assumptions before scaling, and consider offering introductory samples to win initial trial orders quickly.

What operational steps reduce return rates for exported erotic apparel?

Reducing return rates improves margins and reputation in export business. Start with thorough tech packs and graded blocks to ensure size consistency. Run full wash and wear tests on pilot samples to validate colorfastness and construction durability. Implement staged inspections during production to catch defects early. Provide clear care labels and fit notes to buyers so retailers can guide end customers correctly. Use quality trims and reinforced seam work for stress points, particularly in elastic attachments. Finally, include a modest buffer of replacement units for each order to resolve buyer claims quickly. These operational steps reduce returns and foster repeat purchasing behavior among wholesale clients.