What is a 3 Phase Pad Mounted Transformer?

-

A 3 phase pad mounted transformer steps down high voltage for efficient power distribution. Learn about sizes, technical specs, installation.

1. Definition and Types

A 3-phase pad mounted transformer steps down high voltage electricity to a lower, usable level for residential, commercial, or industrial purposes. People typically use this type of transformer in areas with underground power lines, as it provides a more efficient and reliable distribution system. Engineers install these transformers on a concrete pad, protecting them from physical damage with robust enclosures. Designers create these transformers to serve a variety of power needs.

Types of 3-Phase Pad Mounted Transformers

-

Oil-filled Transformers

Manufacturers design oil-filled 3-phase pad mounted transformers with insulating oil that helps dissipate heat, preventing the transformer from overheating. These transformers prove highly reliable, and their efficient cooling systems and ability to handle high power loads have made them a preferred choice for decades. The oil also acts as an insulator, preventing electrical arcing and ensuring safe operation.

-

Dry-type Transformers

Unlike oil-filled transformers, dry-type transformers do not use liquid coolant. Instead, they rely on air or other insulating materials to maintain safe operating temperatures. These transformers are commonly used in indoor applications or areas where fire safety is a major concern. While they may have a lower cooling capacity than oil-filled units, dry-type transformers offer enhanced safety and are more environmentally friendly.

Standards for 3-Phase Pad Mounted Transformers

-

CSA C227.4 and C227.5

These Canadian standards specify the requirements for pad-mounted transformers and help ensure that manufacturers design transformers to meet rigorous safety and performance criteria. The standards provide guidelines for insulation, temperature ratings, and seismic performance. Compliance with these standards guarantees that transformers operate safely and can handle power demands across various applications.

-

IEEE C57.12.34

The IEEE C57.12.34 standard defines the necessary characteristics and testing methods for pad-mounted transformers. It covers the electrical, mechanical, and environmental aspects that guarantee the transformer’s efficiency, reliability, and safety. The standard requires manufacturers to build transformers that consistently deliver reliable performance over extended periods.

2. Technical Specifications

Electrical Properties

The electrical properties of a 3-phase pad mounted transformer play a key role in its functionality and efficiency. These properties include:

-

Primary Voltage

A 3-phase pad mounted transformer typically operates with a primary voltage ranging from 2400V to 34,500V, depending on the model and its intended use. The transformer steps down this high voltage to a lower secondary voltage, making it suitable for distribution across residential or commercial properties. -

Secondary Voltage

The secondary voltage of these transformers usually falls between 120V and 480V, providing the necessary voltage to power everyday devices, machinery, or entire buildings. -

Load Capacity

A transformer’s load capacity determines the maximum electrical load it can support. This is crucial, especially in large commercial and industrial applications. Typical load capacities for pad-mounted transformers range from 45 kVA to 5000 kVA, depending on the size and the power needs of the area.

Mechanical Properties

Mechanical durability is another critical factor in the design of a 3-phase pad mounted transformer. Key mechanical properties include:

-

Enclosure Material

Manufacturers typically enclose most 3-phase pad mounted transformers in steel enclosures. These enclosures protect the transformers from environmental factors such as rain, wind, and physical impacts. The robust steel construction also prevents unauthorized access and safeguards the transformer from external damage. -

Cooling System

Cooling plays a vital role in maintaining transformer efficiency. Oil-filled transformers use insulating oil to cool the system, while dry-type transformers rely on natural air circulation or external cooling systems. Proper cooling enables the transformer to maintain optimal operating temperatures, preventing overheating and potential damage. -

Seismic and Impact Resistance

Some manufacturers design 3-phase pad mounted transformers to meet seismic standards, especially in earthquake-prone areas. These transformers feature reinforcements to withstand seismic shocks and physical impacts.

-

3. 3-Phase Pad Mounted Transformer Sizes

The size of a 3-phase pad mounted transformer depends on its rated capacity, which varies based on the electrical load it needs to handle. Here’s a table showing common transformer sizes according to CSA and IEEE standards:

| CSA Standard Size | IEEE Standard Size |

|---|---|

| 75 kVA | 45kVA, 75kVA, 112.5kVA, 150 kVA |

| 150 KVA | 225 kVA, 300kVA, 500kVA |

| 225 kVA | 750 kVA |

| 300 kVA | 1000 kVA |

| 500 kVA | 1500 kVA |

| 750 kVA | 2000 kVA |

| 1000 kVA | 2500 kVA |

| 1500 kVA | 3750 kVA |

| 2000 kVA | 5000 kVA |

| 2500 kVA | 7500 kVA |

| 3000 kVA | 10000 kVA |

This table illustrates the variety of sizes available, each suitable for different power requirements. Smaller sizes, such as 75 kVA or 150 kVA, are ideal for residential and small commercial applications, while larger units, such as 5000 kVA or 10000 kVA, are designed to power large industrial facilities.

4. Testing

Testing is essential to ensure that a 3-phase pad mounted transformer meets safety standards and performs reliably throughout its service life. Various tests are conducted, including:

-

Dielectric Strength Test

This test measures the ability of the transformer’s insulating materials to withstand high voltages without breaking down. -

Load Test

The load test ensures that the transformer can handle its rated load without overheating or malfunctioning. -

Temperature Rise Test

This test ensures that the transformer can maintain optimal temperature levels during operation, preventing overheating and potential failure.

5. Packaging

Proper packaging of 3-phase pad mounted transformers is essential to prevent damage during shipping. Transformers are typically packaged using:

-

Protective Foam and Padding

Foam and other cushioning materials are used to prevent impacts and vibrations during transport. -

Weather-resistant Wrapping

Transformers are wrapped in moisture-resistant materials to protect against environmental elements like rain or dust. -

Secure Mounting on Pallets

Transformers are placed on sturdy wooden pallets or in custom crates to ensure secure transport.

6. Installation and Maintenance

Installation

Installing a 3-phase pad mounted transformer requires careful planning. The process typically involves the following steps:

-

Site Preparation

Ensure the site is stable, level, and free of debris. The location should be easily accessible for maintenance and repairs. -

Electrical Connection

Connect the primary and secondary electrical cables to the transformer. Ensure all wiring is properly insulated and securely attached. -

Testing

Perform initial tests to ensure the transformer is functioning correctly before fully powering it up.

Maintenance

Regular maintenance is crucial for extending the lifespan of the transformer. Routine tasks include:

-

Visual Inspection: Check for signs of physical damage or wear and tear on the transformer housing.

-

Oil Level Check: For oil-filled transformers, ensure the oil level is within the recommended range.

-

Cooling System Inspection: Verify that the cooling system is working efficiently and that no blockages or leaks are present.

7. Conclusion

A 3-phase pad mounted transformer is an integral part of modern electrical distribution systems, providing safe and efficient voltage transformation. Whether oil-filled or dry-type, these transformers are designed to handle a variety of power demands in different environments. Regular testing, maintenance, and proper installation are critical to ensuring the transformer operates effectively throughout its lifespan.

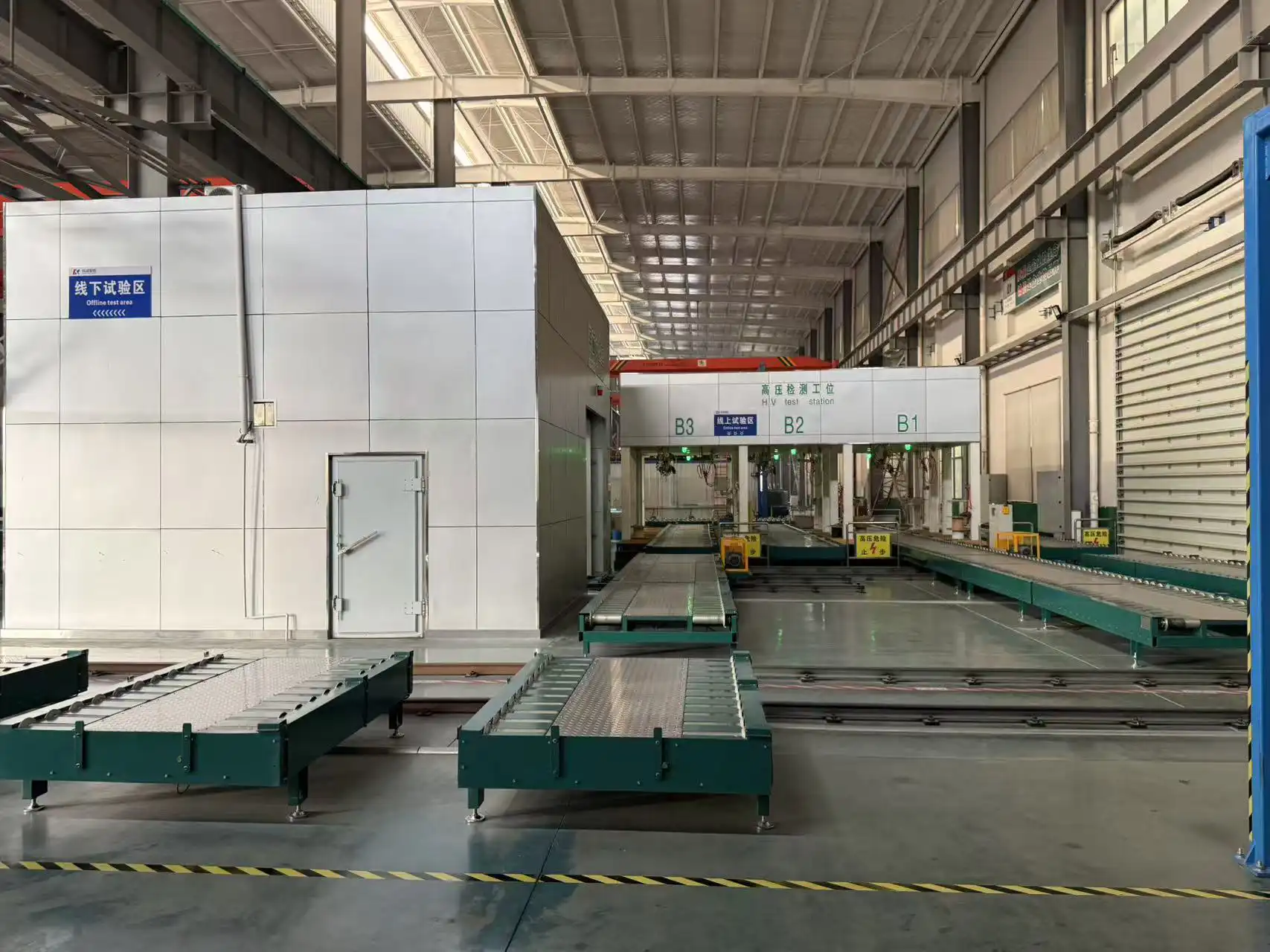

Why Choose Kerun Intelligent Control Transformer?

Kerun Intelligent Control Transformer is a trusted provider of high-quality 3-phase transformers. With over 16 years of experience, Kerun has built a reputation for delivering reliable, durable, and efficient transformers. The company offers cutting-edge technology and complies with international standards such as CSA C227.4 and IEEE C57.12.34. Kerun transformers are engineered to meet the highest safety standards, ensuring that your power distribution needs are met with precision and reliability.

FAQ

What are the main advantages of using a 3-phase pad mounted transformer?

A 3-phase pad mounted transformer provides several advantages, including efficient voltage conversion for both residential and commercial applications, easy installation, and a compact design. It is especially beneficial in areas with underground power lines because you can mount the transformer safely outdoors, which reduces the need for space inside buildings.

How long do 3-phase pad mounted transformers last?

3-phase pad mounted transformer typically lasts between 20 to 30 years, depending on factors such as maintenance, operating conditions, and the environment. Regular inspections and proper maintenance help extend the transformer’s service life.

Can a 3-phase pad mounted transformer be used for large industrial applications?

3-phase pad mounted transformers work well in industrial applications. They come in various sizes, ranging from smaller residential units to larger industrial models. They handle high power demands efficiently, making them an excellent choice for industries that need reliable, continuous power supply.